C-type asteroids are considered to be primitive small Solar-System bodies enriched in water and organics, providing clues for understanding the origin and evolution of the Solar System and the building blocks of life. C-type asteroid 162173 Ryugu has been characterized by remote sensing and on-asteroid measurements with Hayabusa2, but further studies are expected by direct analyses of returned samples. Here we describe the bulk sample mainly consisting of rugged and smooth particles of millimeter to submillimeter size, preserving physical and chemical properties as they were on the asteroid. The particle size distribution is found steeper than that of surface boulders11. Estimated grain densities of the samples have a peak around 1350 kg m-3, which is lower than that of meteorites suggests a high micro-porosity down to millimeter-scale, as estimated at centimeter-scale by thermal measurements. The extremely dark optical to near-infrared reflectance and the spectral profile with weak absorptions at 2.7 and 3.4 microns implying carbonaceous composition with indigenous aqueous alteration, respectively, match the global average of Ryugu, confirming the sample’s representativeness. Together with the absence of chondrule and Ca-Al-rich inclusion of larger than sub-mm, these features indicate Ryugu is most similar to CI chondrites but with darker, more porous and fragile characteristics.

Letter

Ryugu: A brand-new planetary sample returned from a C-type asteroid

https://doi.org/10.21203/rs.3.rs-608561/v1

This work is licensed under a CC BY 4.0 License

Journal Publication

published 20 Dec, 2021

Version 1

posted

You are reading this latest preprint version

C-type asteroids

Ryugu

planetary science

On 6th of December 2020 in South Australia, samples from the C-type asteroid 162173 Ryugu were returned to Earth in the completely leak-tight container within the reentry capsule13, and transported to the curation facility in Sagamihara, Japan, in order to perform the initial descriptions before delivery for in-depth investigations by the nominated analytical teams and for future researches worldwide, in a non-destructive manner and under a non-contaminated condition. The Ryugu sample, the fourth returned samples from extraterrestrial bodies following the past sample return missions after Apollo14 and Luna15 from the Moon, Stardust from comet 81P/Wild216 and Hayabusa from near-Earth S-type asteroid Itokawa17,18, respectively, has sizes ranging from ~8 mm, the largest average diameter, down to fine dusts, with millimeter-scale particles being the most common (see Extended Fig. 1 and Fig. 6 of Tachibana et al. (2021)13).

A total of 5.424 ± 0.217 grams has been collected from Ryugu (see Extended Fig.1), and this has been kept as physically and chemically pristine as possible, with handling only in vacuum or in purified nitrogen without exposure to Earth’s atmosphere. From Chamber A, 3.237 ± 0.002 grams of samples were recovered, which was collected during the first touch-down sampling (TD1) at the equatorial ridge region of Ryugu10. We assume these samples representing the surface materials of Ryugu at the uppermost centimeter-scale layer, and this layer experienced by insolation, radiation, temperature cycling, and micro-meteoritic impacts. From the Chamber C, 2.001 ± 0.002 grams of samples were recovered, and this was collected during the second touch-down sampling (TD2) at a near-by site10 to the artificial crater excavated using the Small Carry-on Impactor (SCI)6,19. We assume part of the samples in Chamber C representing the excavated inner materials excavated by the impact experiments, and that this has not experienced a long-term exposure to space.

The size frequency distributions of particles in Chambers A and C were reconstructed from individual particle measurement (Fig. 1). The wide distribution in sample size has a slope of -3.88 ± 0.25 in the power index. This power index of Chamber A + C particles is steeper than the global average index (-2.65 ± 0.05) obtained for boulders (5 to 140 m in size) on Ryugu or the power index (~2) for gravels (0.02 to several meters in size) at the local touchdown sites11 observed by the telescopic Optical Navigation Camera (ONC-T)20. The steeper power index in the returned particles implies a higher relative abundance of the smaller particles, however several interpretations for the steep power index arise based on the fragile nature of samples from Ryugu, through further fragmentations during impact sampling using a bullet with a cone-shaped collector21 as well as by the shock and vibration undergone during Earth entry in the sample container mounted inside of the reentry capsule22, possible artificial fractionation effects of the better permeability of smaller particles through the sampler horn23, and/or a sampling bias caused by particle handpicking with vacuum tweezers by several personnel as mentioned in the methods. The power index of Chamber A particles, -4.59 ± 0.44, is steeper than those of Chamber C, -3.15 ± 0.20, which shows a much shallower power index in the size range larger than 3 mm. This larger size enrichment in Chamber C would indicate that such larger particles might have been excavated from regolith below the Ryugu’s surface by the SCI impact close to the TD2 site10,19.

From the micrographs of Ryugu particles and their weight analyzed using a balance, the densities of Ryugu particles are estimated based on the assumption mentioned in the method. Their densities are distributed around 1354 ± 290 kg m-3[1] in total, and in detail (1427 ± 325 kg m-3 for Chamber A and 1266 ± 211 kg m-3 for Chamber C)[2] (see Fig. 2). This average density is much lower than the typical grain density of CI chondrites24 at 2110 kg m-3, even lower than the density of 1580 ± 30 kg m-3[3] by gas-filled method24, as well as lower than that of Tagish Lake meteorite25 at 1660 ± 80 kg m-3[4] [5] ,[6] the most porous meteorites ever found on Earth. The calculated micro-porosity of Ryugu samples are 46 %, assuming the grain density of CI chondrites, which is comparable to that of >30 to 50 % (most probably ~50 % for the macro-porosity (vacancies between particles) of ≤ 10 %) which has been estimated for the thermal inertias in centimeter-scale, from remote thermal imaging5 by the Thermal Infrared Imager (TIR)26 and on-site thermal measurements9 with the radiometer (MARA) on the Mobile Asteroid Surface Scout (MASCOT)27. Thus the microscopic observation and weighing for the Ryugu samples reveal their low density and/or high micro-porosity.

Such high micro-porosity materials have never been discovered by any meteorites found on Earth, probably due to breakup by their fragile nature[7] during entry into the Earth’s atmosphere, or a higher abundance of organics compared to any carbonaceous chondrites. Provided that the sample is representative, the global average density (bulk density) of Ryugu is 1190 ± 20 kg m-3[8] , and indicates macro-porosity of ~10% which is contrary to large macro-porosities required for primitive asteroids when typical meteoritic density is assumed28, provided that the returned samples collected from the two sampling sites on the surface of Ryugu represent the entire materials of Ryugu. The low macro-porosity of Ryugu is probably consistent with the packing model using the size-frequency distribution of Ryugu29. A difference in density distribution is found between Chambers A and C, with particles denser than 1800 kg m-3[9] (> 2σ) only found in Chamber A, that being within the density range of typical meteorites found on Earth12, and indicating Ryugu might consist of a mixture of particles from different origins30 or different degree of alteration processes in the parent bodies5,31. The presence of anomalously porous particles discovered on Ryugu (< 1000 kg m-3[10] ) in both Chambers A and C is consistent with discovery of such porous boulders on Ryugu surface by the thermal imager31.

Optical and near-infrared reflectance profile of the samples measured using the optical microscopy, the Fourier-Transform Infrared spectroscopy (FT-IR) and the infrared hyperspectral microscope (MicrOmega)32, 33 show very dark features with an albedo of ~0.02[11] [12] from 0.4 µm to 4µm (Fig.3 and 4), which is in good agreement with the global average of albedo3,4 observed by ONC-T and the Near Infrared Spectrometer (NIRS3)34. The surface composition and inclusions of each sample have a variety [13] [14] but most of them that are considered to represent the typical surface materials of Ryugu have spectroscopically homogeneous and featureless characteristics without apparent high temperature component like chondrule or Calcium-Aluminum-rich-Inclusion (CAI)[15] but with many bright and patchy fine inclusions (See Extended Fig. 1). The surface morphology of the samples is mainly classified into two patterns of rugged and smooth surfaces even in millimeter to sub-millimeter scale, which is similar to the patterns found for centimeter to meter scale3,8 observed by ONC-T and by the imager on MASCOT (MasCAM)35. The presence of different types of surface morphology indicates the past mixing processes of materials from different origin or at the different degree of alteration5,7,30,31. The shape distribution of the particles, which has been studied in the separate paper13, shows variations in aspect ratios, including the elongated and flattened ones, consistent with the flying pebbles that were observed during the sampling operations13.

As a pioneer feature of the sample analyses at this curation phase, a purely non-destructive and non-invasive characterization of the composition is performed by near infrared spectroscopy, through the two complementary instruments. Both FT-IR and MicrOmega analyses for bulk samples from Chambers A and C show spectral profiles, from of 1 to 4 µm wavelength range with a footprint e of ~6 mm diameter (See Fig. 3) by the FT-IR, and as hyperspectral image-cubes of 256x250 pixels (22 µm pixel size), with up to 400 spectral channels covering the 0.99 to 3.65 µm spectral range. Both exhibit clear absorptions at 2.7 µm and 3.4 µm, for both samples. The narrow and relatively deep (~15%) absorption feature peaked at 2.715 µm indicates rather large abundance of hydroxyls (-OH) in the samples, which is comparable to the 2.72 µm absorption feature detected from all over the Ryugu surfaces by NIRS34 but the absorption peak position is in better agreement with the materials excavated by the SCI impact experiment36. MicrOmega high spatial resolution enables to identify few submillimeter grains, with distinct and highly diagnostic spectral features. As an example, an absorption centered around 3.4 µm, also present in FT-IR spectra, corresponds to both carbonates and CH-rich phases. Similarly, an absorption centered around 3.1 µm is interpreted as related to NH-rich compounds, as it has been postulated to be similar to that observed on 1 Ceres37. These detections are witnesses of the aqueous alteration in Ryugu parent body, and coupled to of the non-detection of high temperature component like chondrules and CAIs, they point towards the Ryugu parent body being more similar to CI chondrites than to any other types of meteorites found on the Earth (see Extended Table 1). Details of the MicrOmega findings are presented in a companion paper31.

[16] High-resolution (5 µm/pixel) optical microscopic imaging through five filters (0.40 µm (ul), 0.48 µm (b), 0.55 µm (v), 0.59 µm (Na), and 0.70 µm (w)), compatible with the ONC-T camera of Hayabusa23,7, was conducted for bulk[17] [18] samples from Chambers A and C (see Fig. 4). The dish-averaged spectra and reflectance of Earth-returned samples from 0.48 - 0.86 µm (b to x band on ONC-T) agree well with the disk-averaged spectra of Ryugu3; very flat spectra consistent with Cb type and low (0.02 at v band) reflectance under the geometric condition with incidence, emission and phase angles of 30°, 0°, and 30°, respectively. This agreement indicates that Earth-returned samples well represent the Ryugu surface materials. Both visible and infrared reflectance of the samples from the Chamber A and C is brighter than those of remote sensing data taken by ONC-T3,7,38 and NIRS34,36 beyond their observation and analytical errors (Fig. 3 and 4), which is supposed to be attributed to difference of surface condition of samples between asteroid surface and obtained samples and/or possible contribution of reflected light from the bottom surface of the sapphire dishes. Infrared reflectance of the Chamber A bulk samples is brighter than that of the Chamber C in both data taken by the FT-IR and the MicrOmega, although some variations in wavelength exist in that of the MicrOmega results33. This tendency is inconsistent with results of the NIRS3 data, which shows deeper absorption in 2.72 µm close to the TD2 site compared to other surface materials on Ryugu36, while it is consistent with ~20% darker reflectance in 0.55 µm for ejecta around the SCI crater compared to other Ryugu surface observed by ONC-T 39. Although optical and infrared microscopic images show that Ryugu sample particles exhibit many bright spots (Extended Fig.1), most bright spots disappear at a different viewing geometry so that they are not intrinsic to compositional variation (e.g., CAIs and chondrules) but caused by different photometric conditions33. Many bright spots found on the surface of boulders in the on-asteroid images8, but most of them might be caused by photometric effect.

Our initial observations for the entire set of returned sample in the lab demonstrate that Hayabusa2 retrieved the representative and unprocessed (albeid slightly fragmented) Ryugu sample. Our data further expands an idea based on the remote sensing observations that Ryugu is dominated by [19] hydrous carbonaceous chondrite-like materials, somewhat similar to CI chondrites, but with darker, more porous, and more fragile nature. This inference should be further corroborated by in-depth investigations hereafter by state-of-the-art analytical methods with higher resolution and precision. Those initial descriptions by Hayabusa2 provide a good showcase for future returned sample curation.

Hayabusa2 sample recovery and transportation to the Curation Facility without leaking.

On 5 December 2020 ,the reentry capsule was released from the spacecraft and enter the Earth’s atmosphere on 6 December 2020 , after a successful returning cruise from Ryugu to the Earth. The reentry capsule retrieval operation was carried out complying strictly to the Australian COVID-19 regulations. The landing area of the capsule was determined by receiving a beacon signal transmitted from the capsule using five antennas installed at different locations. The Marine radar systems and two Drones were also used for this retrieval operation of the capsule, the heat shields, and the parachute. The reentry capsule was located nearby the parachute, which was found from the helicopter observation. The safety check of the capsule was first completed at the landing location because pyrotechnic devices were used for the parachute deployment and separation. No damage to the capsule was observed, and the capsule was transported back to a Quick Look Facility (QLF) prepared in the Woomera Prohibited Area (WPA) with a permission from the Australian safety officer.

The reentry capsule was recovered from the landing site in the WPA, South Australia five hours after its landing, and transported to the QLF. The capsule was introduced into the clean booth in the QLF and the sample container was extracted from the capsule and cleaned on its outer surface after the safety check. The temperature monitor attached to the sample container indicated that the container was never heated up to 65°C.

The container was installed on the Hayabusa2 GAs Extraction and Analysis system (GAEA). After the overnight evacuation of the vacuum line of GAEA, on Dec. 7, the bottom of the sample was pierced with a tungsten carbide needle to release sample volatile components held inside the sample container22. The container was in vacuum, indicating the container seal held during reentry and therefore low terrestrial contamination. The gas extracted from the sample container was split into four gas tanks at room temperature, and the residual gas in the system was then trapped into two gas tanks cooled at liquid nitrogen temperature. A fraction of the gas was analyzed by a quadrupole mass spectrometer (WATMASS, Tokyo Electronics). The sample container was put into a nitrogen-purged anti-vibration transportation box and was safely transported to Extraterrestrial Sample Curation Center (ESCuC) in the Sagamihara Campus of JAXA on 8 December 2021 (~57 hours after the capsule landing). Then a heat shield made of carbon reinforced plastic was removed from an outer lid of the container after drilling work with a milling machine to expose head of bolts and remove them. The Hayabusa2 sample container was sealed with the metal-to-metal sealing system21,22. The container lid was pressed against the container edge with a pressure load of ~2700 N through pressure springs. To open the container in the clean chamber designed for Ryugu samples in vacuum, the container was installed into the container opening system. The pressure springs and the outer lid with latches were then taken apart from the container while keeping the pressure load constant. The container with the opening system was the attached to the clean chamber, designed to maintain the Ryugu samples in vacuum, on Dec. 11 (132 hours after its Earth landing) and was opened on Dec. 14 after the chamber evacuation.

As outer surface of the container was cleaned, the outer lid was firstly anchored to access to an inner lid, then the inner lid was anchored with rods to remove the outer lid and a frame for latches. Finally, the inner lid was anchored with the container opening system.

The Curation Facility for Hayabusa2 and its cleanliness control.

The concept of Hayabusa2 curation is to treat the returned samples for the initial description in the non-destructive manner and the delivery for further detailed investigations without any contamination of terrestrial materials and exposure to the terrestrial atmosphere. Therefore, the curation facility is equipped in the ISO 6 or Class 1000 clean room (1000 dust particles of ≥ 0.5µm in diameter in cubic feet)40. The clean chambers (CCs) for Hayabusa2-returned samples are prepared for handling samples under vacuum or ultra-purified nitrogen atmosphere without exposing to terrestrial atmosphere41. They are composed of five independent chamber; CC3-1 for opening the container in vacuum, CC3-2 for opening the chamber A of the catcher and remove a few particles from the chamber in vacuum, CC3-3 for exchanging environment from vacuum to purified nitrogen, CC4-1 for dismantling the catcher to extract the samples from each chamber, and CC4-2 for observation and weighing the samples. All the sample holders, pick-up devices, sample holders, and other jigs and tools used in the clean chambers are specially cleaned to avoid contaminations and their materials are highly limited to minimize the effect of chemical reactions with the samples42.

Pick-ups of the Hayabusa2 samples from the container

As the sample container opening system was connected to the CC3-1 with dry air purged condition, the chamber was evacuated to reach high vacuum as 10-6 Pa. Then the chamber was in static vacuum condition to open the inner lid of the container. Soon after opening the container, the chamber was evacuated again. The sample catcher which is combined with the inner lid was extracted from the container and bottom of the container was left behind the chamber. Then the catcher was turned upside down to make the cover of Chamber A of the catcher face upward, and it was transported from the CC3-1 to the CC3-2 and a gate valve between them was closed. In the CC3-2 of vacuum condition, the surface of the cover of the Chamber A was firstly cleaned with a Teflon spatula. Then all the screw bolts of the cover were unscrewed and the cover was removed with an electrostatic chuck to expose samples inside the Chamber A of the catcher. A large numbers of black particles of > mm size were observed inside the Chamber A.

A few particles of mm-size were removed from the chamber with a sample handling tool equipped with the CC3-2 and put into a quartz glass dish. A cover made of quartz glass was attached on the opening of the Chamber A of the catcher, and the catcher was transported from the CC3-2 to the CC3-3 and the gate valve between them was closed. The CC3-1 and CC3-2 continue being evacuated after that. The CC3-3 was slowly purged with purified nitrogen to reach atmospheric pressure. After that, the catcher was handled with tools and jigs manipulated with Viton-coated butyl gloves equipped in the CC3-3, CC4-1 and CC4-2. Firstly, a jig for handling was attached to the catcher and the screw bolts to connect the catcher with the inner lid were removed to separate the catcher from the lid.

Then the catcher was transported to CC4-2 through CC4-1 to measure its weight with a balance equipped in the CC4-2. Based on the design weight of the catcher and a tare weight of the attached jig, the total weight of samples inside the catcher is calculated to be 5.424 ± 0.217 grams. The balance used for weighing is Mettler-Toledo XP404s, modified on its outer cover from its original to that made of stainless steel 304 sealed with Viton and on its power and signal cables from its originals to those coated by Teflon tubes.

An optical microscope Nikon SMZ1270i with XYZ electric motors system is equipped above the CC4-2, and black particles inside the chamber A of the Catcher was photographed with the microscope. And then the catcher was transported to the CC4-1 and it was dismantled with tools and jigs to extract samples from each of the Chambers (A, B and C) to containers made of sapphire glass, set underneath funnels made of stainless steel 304. After several large particles were handpicked directly from the opening of the funnels with a vacuum tweezer, samples from the Chamber A and C were divided from the funnels into three sapphire containers with a spatula made of stainless steel. Samples inside the Chamber B, which was exposed to the sampler horn after the TD1 and before the TD2, were also recovered into a sapphire container, which are only a small amount of powders of 13 ± 0.5 mg, indicating only a limited amount of samples should be mixed up between three Chambers. The samples in the sapphire containers were measured their weights and spectral characters with the balance, an FT-IR, a MicrOmega and a visible spectrometer. Then particles of >1mm in size in the container were handpicked one by one with a vacuum tweezer having a nozzle made of stainless steel 304 into a sapphire dish for individual particles to be photographed, weighed, and measured with FT-IR and MicrOmega.

These obtained data are catalogued for further detailed researches that starts in summer 2021. Further, the sample will be open to the community and distributed through the Hayabusa2 Sample Allocation Committee in summer 2022.

Outline of measurements for sample description

Multiband optical images of Ryugu samples were taken using a nadir-viewing a nadir-viewing camera system with a macro lens and a CMOS detector covering from 0.48 - 0.86 µm with illumination at 30° from the nadir. In order to obtain high-resolution (~5 µm/pix) images, we used a nadir-viewing Nikon microscope with the same illumination angle. We used 5 filters (b: 0.48µm, v: 0.55 µm, Na: 0.59 µm, w: 0.70 µm, x: 0.86µm) compatible with the optical navigation camera telescope ONC-T of Hayabusa23,20 to the illumination for macro lens measurements and 4 filters (b, v, Na, and w) for microscope measurements.

Spectroscopy of Ryugu samples

The FT-IR used for this study is JASCO VIR-300, equipped to the CC4-2. Its can measure infrared spectrum from 1.0 µm to 4.0 µm in wavelength. Its minimum beam spot in focus position sizes 1 mm, and a nominal beam spot for bulk sample measurement sizes 2 mm. Incident beam comes through a sapphire viewport to illuminate samples inside an FT-IR chamber attached to the CC4-2 of purified nitrogen condition. Before and after the sample measurement, Both its incident and emission angles of infrared light are designed as 16 degree, thus phase angle for the samples is 32 degree. The NIRS3 spectrum was created by averaging 128 spectra acquired on May 15, 2019 (see the Extended Data Table 2 of Kitazato et al. (2021)43 for details). Its reflectance values have been corrected to the same viewing geometry (incidence = 16˚, emission = 16˚, phase = 32˚) using the latest photometric model44. Error bars are 1-sigma. The instrument which includes incident and reflected light paths is purged with nitrogen to decrease influences of absorption of atmospheric molecules like H2O and CO2. Infragold is measured before sample measurement for compensation of the background.

The detailed method about MicrOmega is detailed in another paper31. MicrOmega is mounted on the dedicated chamber attached to CC3-3. The samples are on the XYZ and rotation position changeable stage within the cleaned conditions, and observed with the MicrOmega through the sapphire window.

Density determination of Ryugu samples

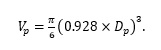

The sizes of Ryugu particles are measured from their optical microscope images taken after their separation into individual containers. Note that separation of particles with the tweezer was made by curatorial members of the ESCuC, which might possibly cause a sampling bias. Major and minor diameters are calculated based on eclipses circumscribed to the binarized images of particles, and averages of the major and minor diameters are used as the size of the particles, Dp. A cumulative number of particles to their average diameters is plotted as Fig. 1, and a power index fitting to the distribution is calculated by maximum-likelihood fitting methods with goodness-of-fit tests based on the Kolmogorov–Smirnov statistic45,46. The volume of Ryugu particles is calculated as a following formula based on the reference47;

The densities of particles are calculated from the volumes calculated with the formula and weights measured with the balance in CC4-2 (Fig. 2). Typical errors of the densities range from 0.03 to 0.50 g/cm3.

- Rivkin, A. S. et al. in Asteroids IV (eds Michel, P. et al.) 65–87 (Univ. Arizona Press, 2015).

- Watanabe, S. et al. Hayabusa2 arrives at the carbonaceous asteroid 162173 Ryugu—a spinning top-shaped rubble pile. Science 364, 268–272 (2019).

- Sugita, S. et al. The geomorphology, color, and thermal properties of Ryugu: implications for parent-body processes. Science 364, eaaw0422 (2019).

- Kitazato, K. et al. Surface composition of asteroid 162173 Ryugu as observed by the Hayabusa2 NIRS3 instrument. Science 364, 272–275 (2019).

- Okada, T et al. Highly porous nature of a primitive asteroid revealed by thermal imaging. Nature 579, 518-522 (2020).

- Arakawa, M. et al. An artificial impact on the asteroid162173 Ryugu formed a crater in the gravity-dominated regime. Science 368, 67-71 (2020).

- Morota, T. et al. Sample collection from asteroid (162173) Ryugu by Hayabusa2: Implications for surface evolution. Science 368, 654-659 (2020).

- Jaumann, R. et al. In-situ investigation of asteroid (162173) Ryugu by the Mobile Asteroid Surface Scout (MASCOT) camera (MASCam). Science 465, 817–820 (2019).

- Grott, M. et al. Low thermal conductivity boulder with high porosity identified on C-type asteroid (162173) Ryugu. Nat. Astron. 3, 971–976 (2019).

- Tsuda, Y. et al. Hayabusa2 mission status: Landing, roving, and cratering on asteroid Ryugu. Acta Astron. 171, 42-54 (2020).

- Michikami, T. et al. Boulder size and shape distributions on asteroid Ryugu. Icarus 331, 179-191 (2019).

- Flynn, G. J., Consolmagno, G. J., Brown, P. and Macke, R. J. Physical properties of the stone meteorites: implications for the properties of their parent bodies. Chem. Erde 78, 269–298 (2018).

- Tachibana, S. et al. Pebbles and sans on asteroid (162173) Ryugu: On-site observation and returned particles from two landing sites. Submitted to Science.

- Turner, G. Argon-40/ Argon-39 dating of Lunar rock samples. Science 167, 466-468 (1970)

- Barsukov, V. L. Preliminary data for the regolith core brought to earth by the automatic lunar station Luna 24. Proceedings 8th Lunar Science Conference, 3303-3318 (1977).

- Brownlee, D. et al. Comet 81P/Wild 2 under a microscope. Science 314, 1711-1716 (2006).

- Nakamura, T. et al. Itokawa dust particles: A direct link between S-type asteroids and ordinary chondrites. Science 333:1113–1116 (2011).

- Nakamura, E. et al. Space environment of an asteroid preserved on micrograins returned by the Hayabusa Spacecraft. Proc. Nat. Am. Sci., 109, E624-E629 (2012).

- Saiki, T. et al. The Small Carry-on Impactor (SCI) and the Hayabusa2 impact experiment. Space Sci. Rev. 208, 165-186 (2017).

- Kameda, S. et al. Preflight calibration test results for Optical Navigation Camera Telescope (ONC-T) onboard the Hayabusa2 spacecraft. Space Sci. Rev. 208, 17-31 (2017).

- Sawada, H. et al. Hayabusa2 sampler: Collection of asteroidal surface material. Space Sci. Rev. 208, 81-106 (2017).

- Okazaki, R. et al. Hayabusa2 Sample Catcher and Container: Metal-Seal System for Vacuum Encapsulation of Returned Samples with Volatiles and Organic Compounds Recovered from C-Type Asteroid Ryugu. Space Sci. Rev. 208, 107-124 (2017).

- Sawada, H. et al. Hayabusa2 sampler: Collection of asteroidal surface material. Space Sci. Rev. 208, 81–106 (2017).

- Consolmagno, G. J. and Britt, D. T. The density and porosity of meteorites from the Vatican Collection. Meteoritics Planet. Sci. 33, 1231-1241 (1998).

- Zolensky, M. E. et al. Mineralogy of Tagish Lake: An ungrouped type 2 carbonaceous chondrite. Meteoritics Planet. Sci. 37, 737–761 (2002).

- Okada, T. et al. Thermal infrared imaging experiments of C-type asteroid 162173 Ryugu on Hayabusa2. Space Sci. Rev. 208, 255–286 (2017).

- Grott, M. et al. The MASCOT Radiometer MARA for the Hayabusa2 mission. Space Sci. Rev. 208, 413-431 (2017).

- Britt, D. T. and Consolmagno, G. J. Stony meteorites porosities and densities: A review of the data through 2001. Meteoritcs Planet. Sci. 36, 1161-1180 (2002).

- Grott, M. et al. Macroporosity and Grain Density of Rubble Pile Asteroid (162173) Ryugu. J. Geophys. Res., 125, e2020JE006519 (2020).

- Tatsumi, E. et al. Collisional history of Ryugu’s parent body from bright surface boulders. Nature Astron. 5, 39-45 (2021).

- Sakatani, N. et al. Anomalously porous boulders on (162173) Ryugu as primordial materials from its parent body. Nature Astron. Doi:10.1038/s41550-021-01371-7 (2021).

- Bibring, J.-P. et al. The MicrOmega Investigation onboard Hayabusa2. Space Sci. Rev. 208, 401-412 (2017).

- Pilorget, C. et al. submitting to Nature Astron.

- Iwata, T. et al. NIRS3: The Near Infrared Spectrometer on Hayabusa2. Space Sci. Rev. 208, 317-337 (2017).

- Jaumann, R. et al. The camera of the MASCOT asteroid lander on board Hayabusa2. Space Sci. Rev. 208, 375-400 (2017).

- Kitazato, K. et al. Thermally altered subsurface material of asteroid(162173) Ryugu. Nature Astron. 5, 246-250 (2021).

- Usui, F. et al. AKARI/IRC near-infrared asteroid spectroscopic survey: AcuA-spec. Publ. Astron. Soc. Japan., 71, 1-41 (2019).

- Tatsumi, E. et al. Updated inflight calibration of Hayabusa2's optical navigation camera (ONC) for scientific observations during the cruise phase. Icarus 325, 153–195 (2019).

- Honda, R. a personal communication.

- McCubbin, F. et al. Advanced curation of astromaterials for planetary science. Space Sci. Rev. 215: 48 (2019).

- Yada, T. et al. Hayabusa-returned sample curation in the Planetary Material Sample Curation Facility of JAXA. Meteoritics Planet. Sci. 49, 135–153 (2014).

- Yoshitake, M. et al. Cleanliness level of the Extraterrestrial Sample Curation Center of JAXA. JAXA Research and Development Report, JAXA-RR-20-004E,1-30 (2021).

- Kitazato, K. et al. Thermally altered subsurface material of asteroid (162173) Ryugu. Nat. Astron. 5, 246-250 (2021).

- Pilorget, C. et al. Global-scale albedo and spectro-photometric properties of Ryugu from NIRS3/Hayabusa2, implications for the composition of Ryugu and the representativity of the returned samples. Icarus 355, article id. 114126 (2021).

- Clauset, A. et al. Power-Law Distributions in Empirical Data. SIAM Rev. 51, 661-703 (2009).

- Tancredi, G. et al. Distribution of boulders and the gravity potential on asteroid Itokawa. Icarus 247, 279-290 (2015).

- Bagheri, G.H. et al. On the characterization of size and shape of irregular particles. Powder Technol. 270, 141–153 (2015).

- Pieters, C. M. Strength of mineral absorption features in the transmitted component of near‐infrared reflected light: First results from RELAB. J. Geophys. Res. 88, 9534–9544 (1983).

- Matsuoka, M. et al. An evaluation method of reflectance spectra to be obtained by Hayabusa2 Near-Infrared Spectrometer (NIRS3) based on laboratory measurements of carbonaceous chondrites. Earth Planets Space 69, 120 (2017).

- Hutchison, R. Meteorites A petrologic chemical and isotopic synthesis. (Cambridge Univ. Press, 2004).

- Nakamura, T. et al. Mineralogy and noble-gas signatures of the carbonate-rich lithology of the Tagish Lake carbonaceous chondrite: evidence for an accretionary breccia. Earth Planet. Sci. Lett. 207, 83-101 (2003).

- Hezel, D. C. et al. Modal abundances of CAIs: Implications for bulk chondrite element abundances and fractionations. Meteoritics Planet. Sci. 43, 1879–1894 (2008).

- Beck, P. et al. Transmission infrared spectra (2–25 µm) of carbonaceous chondrites (CI, CM, CV–CK, CR, C2 ungrouped): Mineralogy, water, and asteroidal processes. Icarus 229, 263–277 (2014).

Extended Table 1: Summary table of Ryugu samples compared with meteorites25,28,50-53, updated from Jaumann et al. (2019)8.

|

|

Reflectance at 0.55 µm |

CAIs (vol%) |

Chondrules (vol%) |

Bulk density (kg m-3) |

2.7 µm band intensity |

|

Ryugu |

~0.02 |

Not observed |

Not observed |

1354 |

0.15 |

|

CI |

0.063 |

<0.01 |

0 |

2110 |

- |

|

Tagish Lake |

0.02 |

rare |

<17 |

1660 |

0.06 |

|

CM |

0.065 |

1.21 |

20 |

2120 |

0.07-0.22 |

|

CR |

- |

0.12 |

55 |

3100 |

0.006-0.165 |

|

CO |

0.10-0.13 |

0.99 |

40 |

2950 |

- |

|

CV |

0.086 |

2.98 |

45 |

2950 |

0.01 |

There is NO Competing Interest.

- 5.jpg

Extended Fig. 1. Optical microscopic images of bulk samples from Chambers A and C. (a)~(c) are those from the Chamber A and (d)~(f) are those from the Chamber C. Both samples are aggregation of black-colored mm-sized pebbles and sub-mm sized fine powder.

Journal Publication

published 20 Dec, 2021

Version 1

posted

You are reading this latest preprint version